◉ BLOG

To be a pioneer in ocean-going environmental protection with enthusiasm and innovation.

SMDERI-QET’s World-First Full-Process Carbon Capture System for New Bulk Carrier Successfully Passes FAT

Release time :

2025-04-24

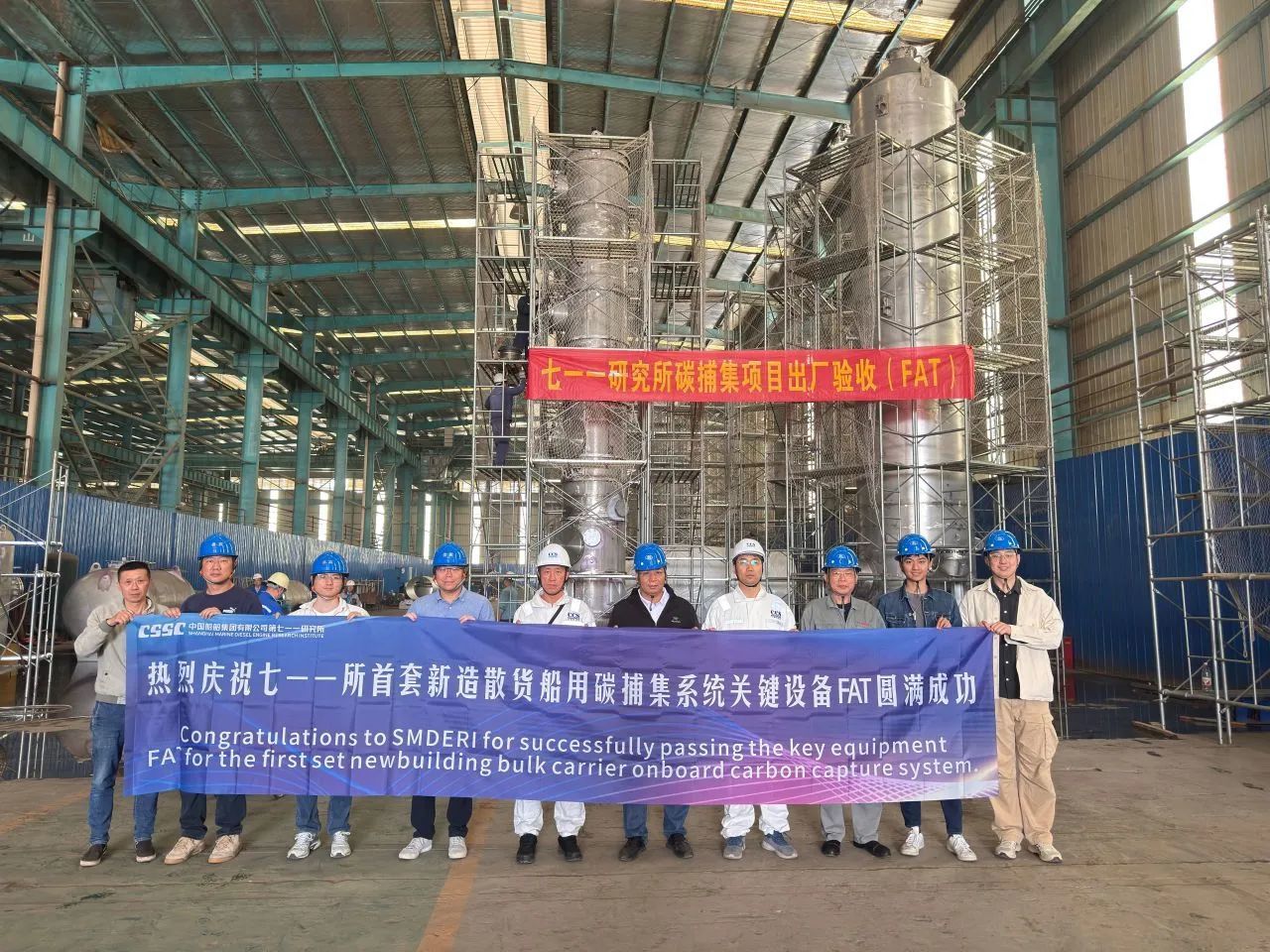

On April 22, Shanghai Qiyao Environmental Technology Co., Ltd. (SMDERI-QET), a subsidiary of China State Shipbuilding Corporation (CSSC), successfully completed a series of Factory Acceptance Tests (FAT) for its tailor-made full-process Onboard Carbon Capture and Storage System (OCCS) designed for Shandong Shipping Corporation’s (SDSC) 82K bulk carrier. This marks the countdown to delivery of the world’s first OCCS installed on a newly built bulk carrier. Led by SMDERI-QET’s in-house R&D, the system integrates end-to-end functionalities for exhaust gas capture, processing, and onboard CO2 storage. It is designed to effectively reduce the vessel’s carbon emission intensity and extend its operational lifecycle, with delivery scheduled for later this year.

Technology Leadership: World's First End-to-End Carbon Capture Solution for New Bulk Carriers

As a core system integrator in the maritime industry, SMDERI-QET has overcome key technical barriers in carbon capture for bulk carriers, pioneering the world's first OCCS that encompasses the entire “capture-liquefaction-storage” process. The system adopts organic amine absorption technology to efficiently extract CO2 from ship exhaust gases, achieving a capture efficiency of over 90% and a CO2 purity level of up to 99.9%, with all key performance indicators meeting world-class standards. Featuring a modular design, the system ensures efficient use of limited onboard space while offering broad applicability and low operating costs. It provides a practical solution to help bulk carriers comply with the increasingly stringent carbon emission regulations set by the International Maritime Organization (IMO).

Industrial Collaboration: Multi-Party Validation of System Stability and Reliability

During the FAT process, representatives from the shipowner, shipyard, and classification society were present to inspect critical components including the absorption tower, desorption tower, CO2 storage tank, compressor unit, and refrigeration unit. A joint commissioning test of the compression-refrigeration system was conducted, showcasing the CO2 compression and liquefaction process. The system’s stability and reliability were comprehensively validated prior to shipment.

Industry Significance: A “China Solution” for Global Maritime Decarbonization

This collaboration with SDSC marks a significant milestone in the joint implementation of green shipping. As one of the first technology companies globally to establish a full-cycle ecological loop for shipboard CO2“capture-storage-offloading-reuse,” SMDERI-QET will continue to strengthen upstream and downstream industry collaboration and promote the large-scale adoption of carbon capture technologies in the maritime sector. It aims to accelerate the global rollout of marine carbon capture technologies, offering a viable “China Solution”for the low-carbon transformation of the international shipping industry, while actively participating in the formulation of relevant standards to promote sustainable green development across the sector.

keyword :

OCCS

Recommended News